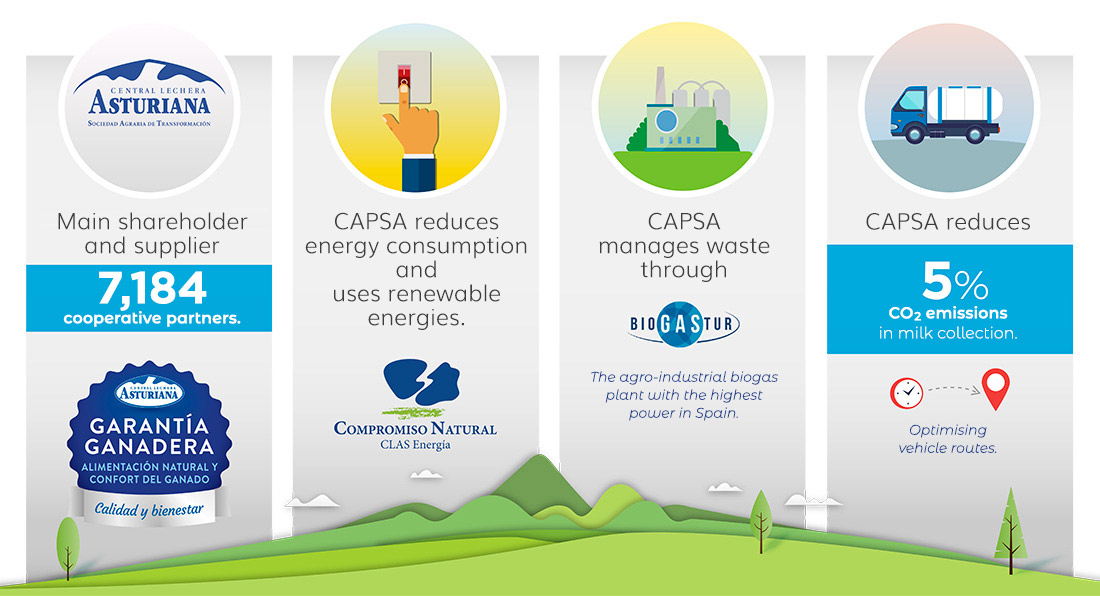

In line with its CSR strategy and Sustainability Policy, CAPSA aims to protect the environment and preserve the natural environment in which it operates.

To achieve this, the dairy firm works towards minimising environmental impact throughout its value chain: from farms to the new materials into which wastes will be transformed.

It therefore contributes to achieving many of the SDGs adopted by the United Nations, specifically: